PLM-Enabled Quality Compliance for Medical Device Part 4 – CAPA

With today’s quality compliance challenges, life science and medical device companies can use product lifecycle management (PLM) as a backbone to support compliance, while enabling continued innovation. PLM connects performance data and enables FDA compliance in six key functions: design controls, document and change controls, corrective and preventative action, material controls, production and process controls and equipment and facility controls.

This blog focuses on the third major quality function: corrective and preventative actions (CAPA). Here’s how life science and medical device companies can implement standard support for CAPA management through the guidance of PLM.

Quality assurance divisions within an organization are required to manage nonconforming events, complaints and audits requirements, among many other commitments1. For global companies, automation, innovation and technology are essential to create and sustain competitive advantage, improve processes and ensure product quality. Without a PLM system in place to link the quality management system with the Quality System Inspection Technique (QSIT) process, the quality system will be inefficient, costly and difficult to manage.

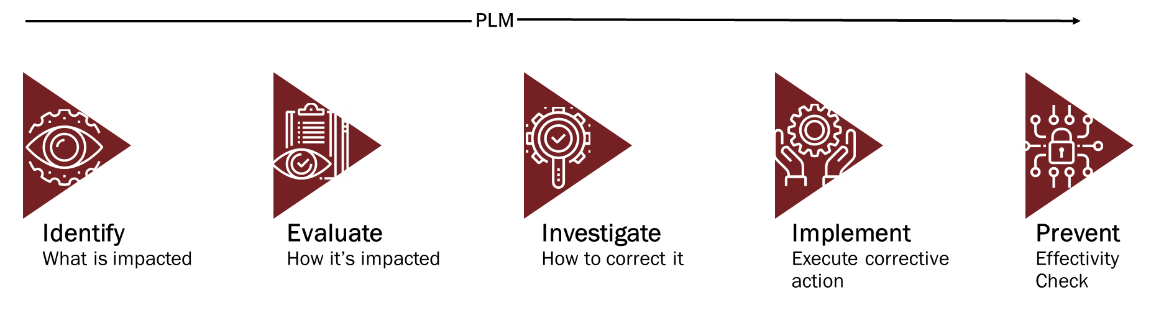

A PLM system will properly handle and report quality events that the organization must be able to identify along with the steps required to comply with various CAPA standards. These steps include: defining the incident and what is impacted, evaluating the root cause of the problem that created the event, investigating and choosing a solution to the problem, executing the chosen solution to correct the problem and implementing a process for effectivity and continuous monitoring to prevent future problems.

With a PLM system, it is easy to achieve the following outcomes related to CAPA:

- Plan and predict quality early during the product design and development

- Share enterprise-wide visibility for quality analysis and feedback

- Close the loop to resolve issues and establish leading practices to improve product and process quality without re-inventing the wheel

- Design quality into products and processes to reduce costs

- Act as a central repository for all product information, including documents, technical illustrations, embedded software, calculations, requirement specifications, CAD models, and more

PLM guides organizations during CAPA to properly handle quality events, determine criticality and implement timely resolutions. Implementing an integrated CAPA capability in PLM enables life science and medical device companies to move from reactive to proactive management of quality issues.

[1] FDA 21 CFR Parts 820.90 and 820.100