We help companies maximize the potential of production systems and workforce with prescriptive analytics and autonomous control to achieve greater throughput and yields.

Facing a tough operating climate of inflationary pressures, high energy prices and ongoing skills shortages manufacturers are looking to drive incremental efficiencies across the organization through technology. Spending in this area increased 30% year-over-year from 2023 with 85% investing in AI.

The need to do more with existing assets and available talent is pervasive from the boardroom to the factory floor. Adoption of emerging technologies and AI that amplify human and machine potential is seen as the best way to mitigate both internal and external risk.

For manufacturers that need to do more with what they already have while increasing operational resilience and driving sustainable growth, autonomous manufacturing enabled by closed-loop optimization is the optimal path toward.

Real Results

- A tire manufacturer drove a 45% reduction in downtime, and produced 550,000 more tires per year

- One Fortune 500 CPG company reduced specification rejections by 30%

- A dairy producer achieved up to a 42% reduction in quality variability and a 6–15% increase in production throughput

- Cement mills increased throughput up to 5.7% and reduced power consumption up to 3.5 KWh per ton of cement

- One petrochemical provider decreased transition times by up to 50%, and increased production by 7%

Unlock the Value of Autonomous Manufacturing for Your Business

Advanced process control (APC) empowers manufacturers to optimize operations for ultimate capacity based on changing conditions. APC comprises of process modeling expertise and techniques such as MPC that understand the limitations of a process and continuously evaluate current and predicted operational data to calculate and make optimal control adjustments. With APC, we empower manufacturers to achieve precision to deliver quality products at speed and scale, while reducing costs and environmental risk.

Watch: How Artificial Intelligence breakthroughs in advanced control are helping customers evolve from Automation to Autonomy.

Our repeatable and adaptable models are honed through successful deployments to deliver better results, faster while maintaining security, safety and stability.

We begin by connecting the individual autonomous systems that make up a factory using a unified methodology and architecture to create a “system of systems” model.

The performance of individual production assets is optimized using model predictive control (MPC) - the most common approach for advanced process control (APC) in plant operations. MPC applications such as "FactoryTalk® Analytics™ Pavilion8® leverage the power of Artificial Intelligence (AI) to adjust variables like temperature, speed, pressure and energy consumption in real-time, improving efficiency, performance and safety.

This degree of visibility and control is then extended from the asset, to the line, and ultimately the plant level, using IoT connectivity to bring operations data to the cloud. This enables visibility and control of the dynamics of the entire plant, mitigating the impact of a disturbance in one department on the rest of the manufacturing process.

The operations data generated from each asset and line is used to train self-optimizing AI models to progressively enhance performance over time. The incremental value created through this process is easily observable on real-time trend and KPI visualizations.

By continuously managing moment-by-moment details, our AI services allow people to focus their intelligence on the bigger picture, while MPC and other tools autonomously drive their process toward the targets they have set.

Closed-Loop Optimization

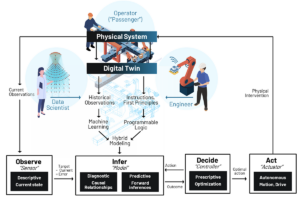

Closed-loop optimization enables physical systems to evolve from automation to autonomy. By developing a digital representation of a physical system (digital twin) and optimizing it with historical and real-time sensor data, the system learns to:

- Observe operating conditions

- Infer desirable outcomes associated with system adjustments

- Decide on the optimal adjustments

- Act on these decisions using physical control elements

The diagram below illustrates the general architecture for closed-loop optimization.

Core Areas for Delivering Impact with Closed-Loop Optimization

Process Optimization

Drive measurable improvements in throughput from existing equipment, in applications such as:

- Dryers and evaporators in mining, food and beverage

- Flotation, crushing and grinding, and kiln control in mining

- Transition in polymer production

- Distillation for ethanol and other compounds

Quality Optimization

Consistently deliver better products and greater yields, through:

- Predictive quality simulation

- Automated product testing

- Equipment optimization

- Automated optical inspection

Energy Optimization

Achieve sustainability goals and improve the bottom line with:

- Raw material availability analytics

- Predictive emissions monitoring and management

- WAGES optimization across the value chain

Supply Chain Optimization

Improve predictability and agility in the face of changing market needs by applying AI and machine learning to use cases like:

- Predictive inventory management

- Warehouse automation

- Automated asset identification

- Route optimization

Technology Partners

Kalypso and Rockwell Automation provide the most advanced level of enterprise process and system orchestration on the market today, with a fully integrated hardware, software and services solution.

- Rockwell’s legacy in industrial control systems and market-leading portfolio of programmable logic controllers, drives and distributed control systems serves as the foundation autonomous manufacturing, capturing production variable data to inform process models and directly implementing prescriptive actions.

- Rockwell’s FactoryTalk™, including LogixAI, Pavilion8 and PlantPAx, and other solutions are complemented by deep partnerships with Microsoft, AWS, PTC and others.

- Kalypso's professional services team brings decades of practical experience and a unique combination of data science, process engineering and consulting expertise that has earned more than 160 patents and driven the successful implementation of over 1,000 process control models worldwide.

Thought Leaders