Businesses are sitting on months, even years, of untapped product data, and they are not capitalizing on the value of today’s product lifecycle management (PLM) capabilities. This is where product lifecycle intelligence (PLI) comes into play.

PLI is an evolution of PLM, focused on mining insights from product development data that has accumulated within PLM environments and other integrated business systems. Powered by advanced analytics and machine learning techniques, PLI helps organizations identify patterns, form predictions and prescribe improvements to product development metrics like data quality, right first-time rates, time to market, regulatory compliance, performance and manufacturability.

Real Results

- 70-90% accuracy in design failure prediction

- 20% reduction in rework and approval time

- 8-10% part error detection rate

- 2-3 months time to market reduction

- 53% reduction in classification time

PLI in Action: A Structured, Data-Driven Approach to Solving Problems

Kalypso’s approach to PLI is powered by a set of proven use cases and methodologies with solutions tailored to meet client needs. The use cases below are just a few of the ways PLI is helping innovators solve key challenges and unlock insights across the product lifecycle.

PLI + PLM

PLM data is available, plentiful and structured, making PLM a logical starting point for many companies, with clear benefits in R&D and new product development.

Data Quality

Enrich PLM data quality - identify duplicates, incomplete, anomalous and erroneous data.

Classification

Organize and define part libraries, predict classification and identify parts for reuse.

Image & Text Analysis

Digitize data within PDF; perform image recognition and comparison.

Rework & Rejection

Predict riskiness of rejection. Identify errors which may result in rework.

Product Design Optimization

Prescribe improved design alternatives to meet innovation objectives.

PLI + Enterprise Systems

For companies with structured data in other enterprise systems, PLI can provide value to additional teams, including manufacturing, supply chain and service.

Product Performance (with IoT)

Bring performance insights from connected products back into the R&D process. Facilitate data-driven design.

Product Quality (with QMS)

Correlate design decisions to product quality results. Predict and avoid quality issues.

Manufacturing Performance (with MES)

Correlate design decisions to manufacturing performance (scrap, yield, quality).

Cost (with ERP)

Leverage cost and procurement data to identify cost reduction opportunities.

Customer Experience (with CRM)

Correlated design decisions to customer experience, adverse events and complaints.

Shaping the AI-Powered Factory of the Future

How We Help Companies Deliver Analytics at Scale with PLI

Identify High Impact Use Cases

We come equipped with a library of proven use cases but work with you to identify the opportunities connected to your business objectives. Use cases with the highest potential impact and value are prioritized first.

Create a “Value First” MVP

Initial development efforts are centered on a narrow use case focus but executed with depth of value creation. We drive towards quick time to value with 8-12 weeks for an initial MVP.

Operationalize and Integrate the Solution into the Work Process

PLI solutions are deployed as digital "advisors" and co-pilots to augment, not replace, human decision power. Solutions are architected so that the analytics engine operates in a stand-alone environment, with the outputs integrated directly into the PLM user interface.

Build the Sustaining Organization to Continuously Deliver Value

Agile processes are established to continuously and quickly scale capabilities (new value creation every 6-8 weeks). We help you establish the delivery organization, equipped with analytics translators operating as the "tip of the spear" to translate business opportunities into analytics solutions. This is backed by a value realization strategy for each PLI solution to ensure results are being measured and realized.

Featured Case Studies & Demos

Deployed via a suite of user-centric apps, PLI addresses core business needs of PLM users, including data migration, new product development cycle times, change management, product quality, supplier management, manufacturability and regulatory compliance.

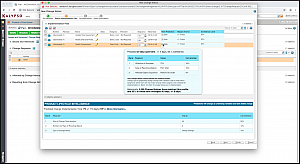

Use Case Demo: PLI for Engineering Change Management

In the following use case demo, we’re a discrete manufacturer making complex products using a PLM application to manage product data.

The engineering change management process is a critical component to managing product improvements and changes to products that are in market. The implementation of these changes is highly variable and one of the biggest contributors to the overall cycle time of a change.

PLI takes the variability and guess work out of the implementation timeline by using the rich dataset that the PLM system has collected. A change manager can now receive real-time feedback on implementation tasks and overall implementation time while simply building the plan.