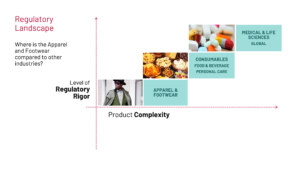

Regulatory Landscape: Where is Footwear and Apparel Compared to Other Industries?

Insights on Supply Chain Traceability and Sustainability

Regulations, as well as industry standards, are being introduced and enforced at a faster pace than ever before. While the regulatory landscape is stricter for other industries, a lot can be learned from the demands of other regulated industries, other geographies and the future that’s looming for the retail footwear and apparel industry.

This article delves deeper into what retail companies can learn from the medical/ life sciences and consumables industries when it comes to regulatory challenges.

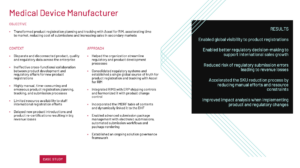

Medical and Life Sciences

It’s no surprise the medical device industry has been quicker to adopt traceability technology as they need to track the origin, content and movement of their products to be safe and compliant for a global market. Medical device companies constantly balance new global standards and increasing regulatory complexity, while trying to expand international sales. Each product they sell needs to be registered in each country they intend to sell. Knowing all restrictions and ensuring they are compliant is a critical step prior to investing in a launch.

We had a client that was growing exponentially and was suffering revenue losses because of product introduction delays. We partnered up to re-look at their Regulatory Information Management (RIM) to validate they were tracking the relationship between artifacts, certificates/report expiration dates and the downstream handoff of information like salability and shipping information.

Not only does a centralized system allow for checking the applicability of a product to a specific market, with the right connectivity in place, companies can prevent the shipment of non-compliant products and risk them being detained.

What did the effort look like?

Interested in hearing more? Check out our latest webinar on the topic.

Consumables

In the food and beverage industry, everyday products must guarantee consumer safety and quality, via traceability, so they know how everything moves in the event of a recall or new substance banning.

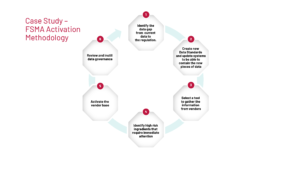

In 2011, there was a new regulation signed into law called the Food Safety Modernization Act (FSMA) – whose goal was to prevent foodborne outbreaks from occurring by , proactively regulating the food industry. One key element of the regulation was to require all allergens, certificates and claims for all ingredients in formulas and products, are tracked. The effort to contact Tier 3-4 suppliers was insurmountable. The F&B industry thought that this regulation would take too long to come into effect, if it even materialized.

We had a client who started the journey in 2017, with an ingredient specification focus, that evolved from a US need to a global traceability and compliance effort. Through this, they are now in better shape to stay ahead of future requests.

What did the effort look like?

FDA mandates and RIM systems are not typical of apparel companies, since usually regulatory is not a key component of the product launch strategy. However, being aware of looming responsibilities, leveraging technology and demonstrating compliance are concepts that are being closely heightened.

Apparel and Footwear - Europe

The regulation disparities between EMEA and North America can be attributed to different factors. Much is about tolerance to risk, trade being harmonized between EU countries, and stronger emphasis on public health and environmental protection.

One key transparency and sustainability initiative in the EU is the digital product passport (DPP). By 2030, every textile product for sale in the European Union will need a DPP that provides information about a product's lifecycle and environmental impact., at the hands of the consumer.

Given that the apparel industry is mainly composed of small and medium-sized enterprises (SMEs), some of the requirements, like DPP, seem like monumental tasks. However, the operationalization has many avenues and can start small, but effective.

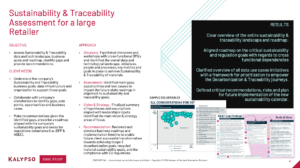

An example of this effort was a client who wanted to identify and prioritize use cases between sourcing, supply chain and traceability- including how they connect, enable or are enabled by Product Lifecycle Management (PLM) and Digital Product Creation (DPC).

What did the effort look like?

US Apparel Starting Conversations

While the European apparel and footwear industry is subject to more regulations than that of North America, our trade with Europe also requires us to be compliant beyond our immediate responsibilities. Leaders must begin intentional traceability conversations on this side of the Atlantic.

The Forced Labor Prevention Act (FLPA) was rolled out in 6 months- whether that was ‘fair’ and whether or not that kind of runway will be repeated or increased, retail footwear and apparel companies should be better protected against the risk of lost sales from having goods held with Customs and Border Protection (CBP).

Leaders aren’t waiting to be told to do it - brands should embrace traceability as part of their DNA and use this as an advantage.

We had a recent client who, trying to be reactive to the headlines in Europe, posed us the challenge of “How to get to tier 4 supply chain traceability?”

What that conversation revealed was that they weren’t doing the ‘easy’ things. Much like the food and beverage example, they needed to get started with the lowest barrier to entry; Get all certifications and compliance audits from their factories in a centralized location and build data in a way that is searchable.

Traceability is a cornerstone of supplier relationships. It is important to also consider your reach to suppliers and where those relationships can improve. Ask questions like:

- How are your specs?

- How is your data?

- What’s transparency like at your brand?

- Is it enough for the future?

Our Recommendation

Let’s start with a high-level framework to get you thinking of where to begin

- Identify: Identify stakeholders and establish clear traceability goals aligned with your brand's values. Perhaps you’ve experienced the risks we already covered which may influence your goals.

- Prioritize: Prioritize initiatives with the highest impact and feasibility to address immediate challenges. Be realistic, aim for the lowest-hanging fruit to start. Expect progress, not perfection.

- Analyze: With priorities in place, you’ll need to analyze your data. Understand your data stream including where the gaps exist and create a roadmap to resolve and enhance the collection of data. How are you harnessing your supplier relationships and the availability of required data?

- Integrate: Leverage existing and research new technology solutions to enhance traceability and transparency. You may already have solutions that aren’t being fully leveraged, or perhaps you're finding the collection of data is either too manual or feels unattainable

The technology landscape is vast, and fragmented, so depending on your data management maturity you may need to take a different approach. Stay tuned for the last Viewpoint in our series where we'll discuss how to get started, including creating a 30-60-90 day plan.