Understanding the Retail Industry's Supply Chain

As we navigate the complexities of our modern world, particularly in the retail industry, one topic repeatedly comes to the forefront: the supply chain. Acting as a vital system that ensures the flow of goods and services, the retail supply chain faces numerous challenges today, including geopolitical tensions, labor issues, and the push for better environmental and social governance (ESG). Historically, the supply chain has evolved through technological advancements, the Industrial Revolution and the rise of globalization and free trade.

These developments made resources more accessible, strengthened economies and created opportunities for businesses worldwide. However, in our post-pandemic world, the intricate web of the retail supply chain is under strain, revealing vulnerabilities and the need for more resilient and sustainable practices. In our latest series, we discuss different aspects of the supply chain including:

- Why supply chain traceability is important in the retail industry

- Where the apparel and footwear industry is compared to others in the regulatory landscape

- What the first 90 days of your traceability journey could look like

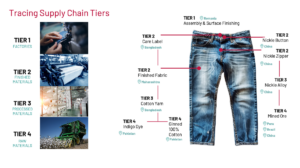

What are Supply Chain Tiers?

Not all suppliers play the same role in the production of products. Supply chain tiers are the level of suppliers involved in the production and delivery of goods from raw materials to finished goods.

In each tier, the facilities and suppliers have a responsibility to ensure that required specifications are met before passing them on to the next tier.

Tier 1: Finished goods

These are the facilities where products are assembled and completed –cutting, sewing, finishing etc. Retailers typically have the closest relationship with Tier 1 suppliers.

Tier 2: Finished Materials

The suppliers who make specific components– like the finished denim fabric, the care labels, zippers and buttons. Tier 2 suppliers work closely with Tier 1 to ensure parts are available for assembly.

Tier 3: Processed Materials

These suppliers provide raw materials for making components like cotton yarn to weave fabric, leather, alloy etc.

Tier 4 : Raw Material

These are facilities where raw materials come from and may initially be processed -like ginned cotton, mined ore, tanning leather.

What is Supply Chain Traceability?

Supply chain traceability is the ability to identify, track and trace elements of a product as it moves along the supply chain from raw materials to finished products.

Why is Traceability Important in Supply Chain?

In the apparel and footwear industry, supply chain traceability is crucial for compliance, protecting brand reputation, and promoting sustainability. As regulations tighten and consumers demand greater transparency, businesses must navigate the challenges of ensuring their products are ethically sourced and meet quality standards. This overview explores the importance of traceability and the risks of neglecting it, including regulatory, reputational, and financial consequences.

Regulatory Non-Compliance

As a result of the Uyghur Forced Labor Prevention Act since July 30th, 2024, 1,661 apparel, footwear and textiles shipments have been detained at US Customs and Border Protection. These shipments have a total value of $69.75M. So far only 400 have been released, 982 have been denied and 279 are still pending.

When the product is detained, the importer of record is served with a detention notice and required to prove within 30 days that the product is not produced with forced labor -meanwhile, they are faced with storage fees. If they can’t prove compliance, they either need to destroy the product and lose its total value, or re-export it and incur export fees.

How does CBP determine the origins of products when proof isn’t available?

Laboratory tests like Isotope analysis (it’s like a fingerprint) can detect if cotton, for example, is sourced from the Xingjiang region where Uygur forced labor is known to be used.

So without traceability, businesses may unknowingly source materials or labor from unethical or non-compliant suppliers, exposing themselves to legal penalties and delayed deliveries due to violations of labor or environmental regulations.

Reputational Damage

In today's socially conscious marketplace, consumers expect transparency and accountability from brands regarding their sourcing and production practices. Failure to trace the supply chain and address issues such as labor exploitation, environmental degradation, or animal cruelty can result in negative publicity, boycotts, and loss of customer trust and loyalty. The ability to legitimately label products with green certifications relies on tracing your supply chain.

According to Gartner, customers want sustainable products. Their research shows that by 2027, 20% of the S&P 500 will cite greenwashing, or positioning a company as environmentally friendly rather than actually minimizing its environmental impact, as a risk factor, strengthening sustainability commitments. It will be more important than ever to be able to be transparent about their efforts in sustainability for their retail supply chain.

In the EU, greenwashing legislation was recently passed that bans companies from making exaggerated and unfounded claims relating to a company’s environmentally friendly actions. Therefore, certifications reliant on traceability are important to have.

Quality and Safety Concerns

As of today, the EU has banned more than 30 substances for use in fashion. Incomplete traceability can compromise product quality and safety standards, as businesses may be unable to verify the authenticity, origin or safety of materials used in their products. This increases the risk of incurred fines, product recalls, customer complaints, and damage to brand reputation.

For example, in a private investigation in Canada testing 38 clothing samples from known brands 1 of 5 contained elevated chemicals. A shocking discovery was a toddler jacket from a fast fashion company that had 20X the amount of acceptable lead in it.

Counterfeit Concerns

Counterfeits cost the global economy an estimated $500 billion a year. By implementing traceability measures in your supply chain, you empower customers to make informed purchasing decisions and uphold the quality standards your brand is known for, ensuring a secure and reliable product experience.

While blockchain technology holds promise for assisting brands and consumers in improving the authentication of materials and products, its effectiveness relies on a fully traced supply chain. By revolutionizing supply chain management, blockchain provides a secure and transparent platform for verifying the authenticity of materials and products, effectively combating counterfeiting.

Cost Inefficiency

In 2023, the fashion industry produced a startling 97 million tons of waste annually, of which 18 million were leftover textiles, 2.5 million were chemical waste, and 3 million were packaging materials. The fashion industry's waste isn't just detrimental to the environment; it's also a significant drain on your business's resources.

By addressing waste through supply chain traceability, you are not only protecting the planet, but also unlocking potential cost savings and efficiency gains.

These are risks that impact the retail footwear and apparel industry and the actions needed to avoid these risks are expanding the regulatory landscape – and we can learn a lot from other industries.

Next up, we'll discuss where the apparel and footwear industry is compared to others in the regulatory landscape.