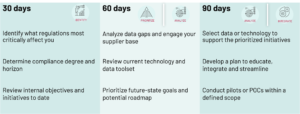

How to Get Started: A 30-60-90-Day Plan

A Plan for Traceability in the Retail Industry

Earlier in our series, we discussed why supply chain traceability is important in the retail industry and where the apparel and footwear industry is compared to others in the regulatory landscape. Now we will dive into what the first 90 days of your traceability journey could look like.

Creating a 30-60-90-day plan for traceability in manufacturing, especially in the retail industry, is key to building a roadmap toward transparency, efficiency, and regulatory compliance. This structured approach breaks down complex traceability goals into manageable steps, which will guide retail leaders through each stage with clear actions and reflection points.

In this guide, we will highlight the key questions to ask at each stage to identify gaps and opportunities, alongside specific actions designed to move you closer to full product traceability or to complete traceability in your manufacturing operations. If you’re ready to embark on this journey but wondering where to start, we’ve mapped it out for you.

The First 30 Days: Establishing Your Foundation

During the first 30 days, the focus is on understanding the regulatory landscape, your current level of compliance, and the objectives that traceability will support within your organization. Start by identifying the regulations that are most pressing for your operations. Are there industry-specific certifications you’ll need to back up your claims?

For instance, if you’re selling products in the U.S., consider the Uyghur Forced Labor Protection Act. Retailers with a presence in the European Union (EU) may also need to anticipate requirements around greenwashing claims (EU greenwashing legislation).

Key Questions to Consider:

- Why is traceability important in manufacturing?

- What upcoming regulations could affect our business?

- Do we have the certifications or documentation to support our traceability claims?

- Do my current business practices match up to leaders in this space?

Next, assess the scope and timelines for compliance. Ask yourself where compliance issues might arise based on your materials and supply sources. For example, do you source cotton from regions impacted by restrictive labor laws? Align these insights with your shipping destinations to understand where compliance efforts need to be focused.

Evaluate your current position using a maturity framework that identifies the key enablers needed to achieve those goals effectively. Clearly document your goals and data needs, as well as new traceability concepts or roles you’ll need to educate your workforce.

Lastly, review your internal objectives and past traceability efforts. Look at existing environmental, social and governance (ESG) targets or customer transparency commitments to see where traceability can support or enhance these goals. If traceability-related risks have impacted your operations in the past, those areas may need immediate attention.

The Next 60 Days: Data and Supplier Engagement

At the 60-day mark, shift focus to identifying data gaps and working with your supplier base. This phase is about understanding what information is lacking and where. Are your traceability challenges mostly internal, or do they require external collaboration? Consider whether your current data sources, such as PLM systems or spreadsheets, allow for easy access and searching. It’s also essential to evaluate whether your current technology efficiently supports your traceability goals and ESG tracking.

Key Questions to Ask:

- Are our traceability gaps internal, external, or both?

- Is our data stored in a way that supports easy access and scalability?

During this phase, prioritize your future-state goals and establish a preliminary roadmap.

Track your progress to desired maturity and formalization, that aligns with your brands objectives, solidifying the key enablers needed to achieve those goals effectively. Look for “quick wins” that could yield significant improvements in efficiency and start developing a plan for comprehensive tracking and tracing.

The Last 90 Days: Integrating and Scaling

In the final 90 days, focus on aligning technology and data tools to support your traceability objectives. Begin by evaluating the technologies available and determining which best fits your needs. Look for initiatives that could justify investments or enhance other areas of the business. As you map out your tech integration plan, prioritize change management and ensure team readiness through targeted education and awareness programs.

Start with small-scale pilots or proofs of concept to validate your approach, then gradually expand these efforts to tackle more complex traceability challenges.

When Should I Start?

The best time to begin improving your supply chain traceability is now. A fully traced supply chain strengthens resilience, boosts efficiency, and supports sustainability goals. As risks continue to mount, a proactive approach to traceability will position your business for long-term success.