Mining, Metals and Cement and Sustainability Q&A

Hear from Kalypso and Rockwell subject matter experts

In a recent interview, Kalypso spoke with Kalypso and Rockwell subject matter experts about the state of the mining, metals and cement industries when it comes to sustainability and the vision for the autonomous fixed plant.

According to Gartner, the key to improving long-term sustainability is by embedding process, task and other related technologies in a competence center. Organizations need to move beyond the technology level to ensure business governance over opportunity discovery, architectural choices and effective change management.

Our interviewees

- Kumar Parekh is the Kalypso principal covering consumer packaged goods and manufacturing in the South Pacific (Australia and New Zealand) region and Kalypso's global mining lead. He brings more than 25 years of data, analytics, product management and consulting experience to Kalypso.

- Len Kosatka has been with Rockwell Automation for 37 years, where he has been an enterprise account manager focused on the metals industry since 2005. Previously he has held positions as an application engineer, technical consultant, senior sales engineer, and marketing manager across several industries that Rockwell serves.

What are we seeing in the mining, metals and cement (MMC) industries in terms of the move from fossil fuels and other non-sustainable energy sources toward renewable sources?

KP: Every process industry requires a reliable supply of power, especially in the mining and metals industry. But this can also include the medical field, with linked laboratories, or the food and beverage industry, where process and production lines are involved.

LK: Shifting to renewable sources has been similarly challenging. A primary consideration for building new plants is a readily available supply of energy. That could include hydroelectric or locally sourced natural gas as fuel for their electrical power generation. Some plants have augmented their electrical supply by adding wind turbines or solar panels. Unfortunately, the physical footprint and reliability of solar and wind are not ideal as the primary source for the .5-2GW demand of these facilities. So, the metals industry has been more focused on utilizing the energy that they are consuming more efficiently. Energy-efficient technology upgrades or process improvements can frequently pay for themselves within a year or two.

How is that impacting the business?

KP: Organizations are being bombarded with varied views and they're reacting based on their readiness, the cost to the business and the technology available in the market to help them reach their goals. At large, we see decision-making being impacted by regulatory requirements, investor agitation, cost and license to operate (from both social perception and the political environment). Depending on the industry, the pressure to move to sustainable energy is mainly driven by regulation since organizations need to export their goods. Each country has different norms and regulations that organizations need to adhere to. Then of course, every organization wants to do things at a minimal cost. Finally, every organization is trying to navigate these shifts in their own way, but social perception of the organization is also a major impact on the business.

There are also other factors many organizations keep in mind when making sustainability decisions. One is the ability to attract talent. Members of the generation currently entering the workforce want to work for an environmentally conscious company. Being energy efficient and reducing their carbon footprints can help companies attract and retain talent.

LK: Regarding regulatory requirements and license to operate, emissions and byproducts are top of mind, especially in markets like the U.S., Canada, and EMEA. Equipment can be installed to monitor and minimize undesirable emissions that occur in those processes. For example, a typical emission from aluminum is carbon dioxide, but carbon monoxide can also be produced if the process is operating in an undesirable manner.

Monitoring and tight control are key to ensuring processes only produce expected emissions within the levels imposed by the relevant regulatory agencies. Companies are also trying to identify solutions for byproducts like red mud (bauxite processing waste), by separating out trace minerals or by repurposing them to make construction materials.

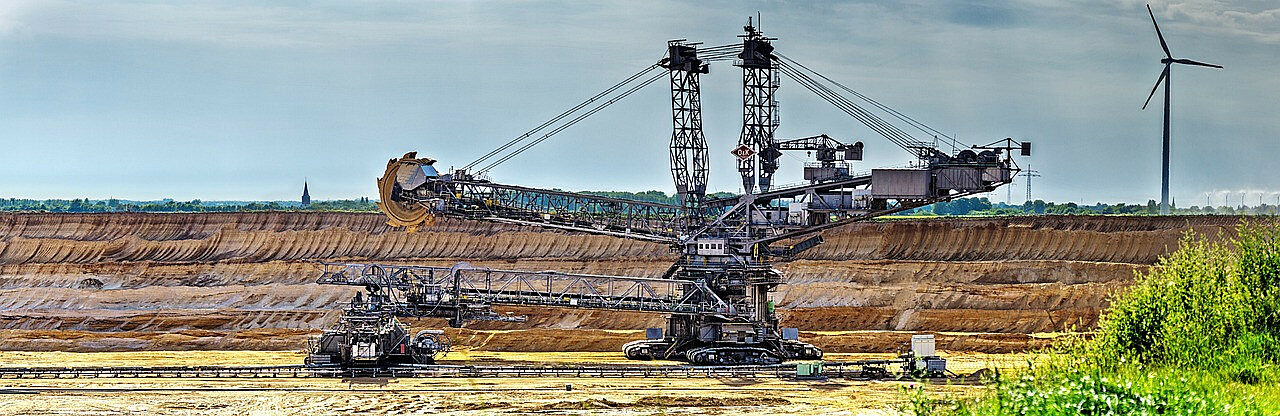

Additionally, companies are looking at the mining process, ie. how can they get to the needed ore without seriously impacting the environment, and how can they then recover the land after extracting that ore. Many mine operators are currently innovating in these areas.

What are the challenges organizations are seeing with electrification and moving to other potentially less reliable energy sources?

KP: Across mining, metals and manufacturing, each stage of a process industry involves emissions and the use of energy. In terms of sustainable sources, the major way power is being generated today is through wind and solar. The challenge is that the effectiveness of both of these sources is variable depending on conditions – such as if the wind drops in a location or if it’s cloudy or rainy for a few days. Dependence on weather conditions means reliability for solar and wind is reduced.

As we talked about, unpredictability in a process industry is a huge issue. One of the ways this is being addressed in the metals industry (and at large) is through energy storage. Batteries are being designed to store energy to prevent interruption. Another challenge is around power grids. Traditionally, power grids have been long transmission lines built over hundreds or thousands of kilometers and were designed to have a power plant. An issue now is the cost and practicality of bringing this power back to the destination of consumption. Building new infrastructure for grid integration is a financial consideration for organizations.

Another financial challenge is related to the regulatory environment as we discussed earlier. Many organizations, and many countries, are grappling with regulations around energy consumption and a shift to renewables, but the absence of a uniform set of rules governing all organizations globally creates uncertainty. Since uncertainty is not favored by investors, organizations may have difficulty getting funding for initiatives that address energy consumption.

LK: The bottom line is that unreliable energy sources are a non-starter for plants with continuous production needs. An anecdote from history can illustrate this well. During World War II, a (failed) German intelligence plot identified aluminum smelters in the U.S. that were producing much of the aircraft-grade aluminum for U.S. fighters and bombers and intended to cut off power to them. While this plan for infrastructure sabotage was discovered, and the saboteurs captured before anything was attempted, it underscores the criticality of avoiding even temporary interruptions, especially for aluminum (which uses parallel batches). Even for the steel industry, which deals in single batches done in series, any disruption to power can cause more issues than just a loss of a few hours of productivity. An unexpected power outage could potentially shut a whole plant down for months.

What is the vision for the autonomous fixed plant?

KP: Whether it's a mine or a manufacturing facility, the idea behind an autonomous fixed plant is to have a connected enterprise. In a connected enterprise, there are multiple levels at play. At the plant level, this deals with control, systems and process engineers. Once you get to the top, you’re looking at using AI and machine learning to predict events and provide insights so that unwanted events can be prevented.

We can help starting from the plant level, but we can also take it up the value chain – starting with strategy and operating model, up to implementing and creating the automation where the components at the ground level are connected, communicating and protected from a cybersecurity perspective and the right data is available at the right time to each level of decision-making. Organizations often have different KPIs associated with various levels of the plant or different role levels, so there may be multiple sets of requirements in terms of production and maintenance of production.

LK: Islands of automation can also pose a challenge for organizations. Many facilities were built in the 1930s or 40s, but over time as companies have expanded or changed to address different marketplaces, they have modified or added only the equipment that was needed to address a given concern.

For example, some steel hot mills are still using 1940s submarine motors that run on direct current (DC). That’s an island of technology, as no one installs DC anymore. Many of those DC mill motors have been converted to AC and are now controlled by variable frequency drives. In the 1970s, 80s, 90s, and 2000s, many of those installations were upgraded with modern sophisticated control systems. So, you could have 1940s technology powering the mill stands, but more current technology controlling them. Plants may have mixed technologies….some areas running on today’s technology, while other areas are using 1970s, 80s, and 90s technology. Trying to get those systems to interact with each other or to provide information to a higher-level plant or enterprise network can prove to be challenging. A specific power-related case is to improve the insight of power consumption down to the device level by adding power monitoring capabilities to the distribution system.

How is the adoption of wind and/or solar power going to impact the industry? How can Rockwell assist in this with services and software?

LK: Companies may use wind and solar to augment their primary source of power, but to be clear, it is not feasible to completely replace that primary source. There is a place for these alternative sources, but it’s small. Wind and solar can help companies offset some of the costs. The power generation group inside Rockwell’s Systems and Solutions Business has helped companies integrate wind and solar into what they’re doing today, using current technology like ControlLogix. Monitoring items, such as WAGES is a practical way of identifying inefficiencies or waste, and then attempting to find a means to improve their consumption.

As an example, power factor (PF) is something plants are especially concerned with, as there are penalties for power factors that are too low. Plants can monitor and then identify processes that significantly impact PF, and then through a combination of scheduling those lines to off-peak time (where possible), and other optimizing efforts, provides a useful strategy for avoiding or reducing those penalties.

How can Kalypso help companies in these spaces?

KP: Kalypso helps clients in their digital transformation journey. It is vital to have a strategy and a roadmap that is endorsed by the executive leadership team and Kalypso can design that strategy and help execute it to drive business results based on process and technology adoption and transformation.

Often, IT / OT and other business functions have differing KPIs and objectives, and having synergy on the strategy and operating model is a key trigger for success.

Depending on the industry, we help deliver solutions that address the convergence of IT / OT, from the machine level and elevating upstream to a plant level and finally towards a fully connected enterprise across multiple manufacturing sites, plants or mines.

The key to enabling digital transformation is having the right data at the right time at the right quality. Our industry-focused solutions like Mining Operations Management, Manufacturing Operations Management, Model Predictive Control, Asset Intelligence and Industrial Data Operations are vital components to the success of your organization's digital transformation journey.