Seamlessly unite design and manufacturing with manufacturing process management

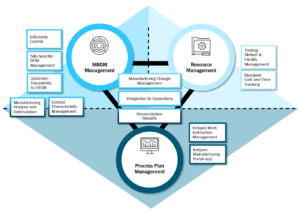

Manufacturing Process Management (MPM) is a crucial part of the digital thread and essential in merging the product digital twin with the operational digital twin during the ‘make’ phase.

It is responsible for managing the resources, people and procedures necessary to manufacture a product, with all its variations, across different locations, keeping everyone in the process updated with the latest information in real time.

MPM closes the loop between product design and manufacturing. As design engineers define a product, manufacturing and process engineers gain instant access to the latest data so they can define and adapt how to produce, maintain, repair or verify that product.

Connecting and centralizing all engineering and manufacturing data ensures that production follows the most current product specifications and work instructions. This enables traceability from design to the manufacturing line, optimizing production and operations and enhancing the visibility of manufacturing resources management and planning.

MPM helps improve quality, decrease risk, reduce rework and reduce cycle times in manufacturing updates.

Common challenges of siloed engineering and manufacturing operations

- Long lead times for testing manufacturability

- Siloed engineering & manufacturing business processes and teams

- Lack of visibility into manufacturing resources (e.g. plants, work cells, latest tooling, process materials, resource skills, etc.)

- Missed opportunities for process improvements due to lack of visibility into in-process controls for quality teams

- Cumbersome impact assessments across R&D, Manufacturing and Operations

MPM Addresses Key Business Imperatives

Flexible Engineering and Agile Manufacturing

Design and manufacture flexibly across the globe to reduce risk and improve responsiveness to change

Product Safety and Quality

Reduce patient safety and product quality issues with improved communication between R&D and manufacturing

Manufacturing Efficiency

Avoid delays, rework and scrap by validating product manufacturability early and implementing manufacturing standards across plants producing same or like products

Improved Time-to-Market

Deliver insights with faster, more robust, detailed and reliable data impact assessments that encompass product and manufacturing

Future-proof Enterprise Architecture

Connect the foundational pieces

Incorporate Smart Connected Operations (SCO) technology

Leverage PLM CAD data to create simulations and emulations of how products will be produced

Operational Efficiency

Enhance visibility and traceability of product and manufacturing data and leverage it to optimize manufacturing processes

Streamline upstream (PLM) to downstream (ERP, MES, etc.)

We offer end-to-end services for manufacturing process management – strategic advisory, implementation and managed services

Key Capabilities

Want to see MPM in action?

Checkout this video of the MPM journey to see how Kalypso can help you seamlessly bridge the gap between process and design.