Two Ways IoT is Disrupting (and Helping) the Manufacturing Process

The internet of things, also known as (IoT), is an emerging technology that has the potential to disrupt the manufacturing industry. It’s about allowing a device with a switch to connect to the internet. For example, a thermostat in your house that is controlled by your phone or a sensor on a CNC machine connecting it to the factory. According to Gartner, approximately 3.9 billion things were connected in 2014 and it is expected to rise to 25 billion by 2020, equating to a 35% annual growth rate.

Factories that are connected to the internet are far more productive and efficient than those that are not. IoT helps manufacturers drive down costs, eliminate inefficiencies, manage workforce skills/gaps and develop new areas to generate business, yet only 10% of industrial operations use IoT, leaving a tremendous growth opportunity for IoT in manufacturing.

In A Look Ahead: An Interview from the Future on the Birth of Digital Manufacturing, we imagine what the near future can be for a manufacturing company building on a core strategy that relies on IoT, business intelligence (BI), and cloud-based applications. But how can this strategy usher in a new digital age of innovation?

How is IoT Disrupting the Manufacturing Process?

There are endless possibilities on how IoT can be used in both discrete and process manufacturing. Two primary areas are Machine to Machine Communication and Product Development Processes.

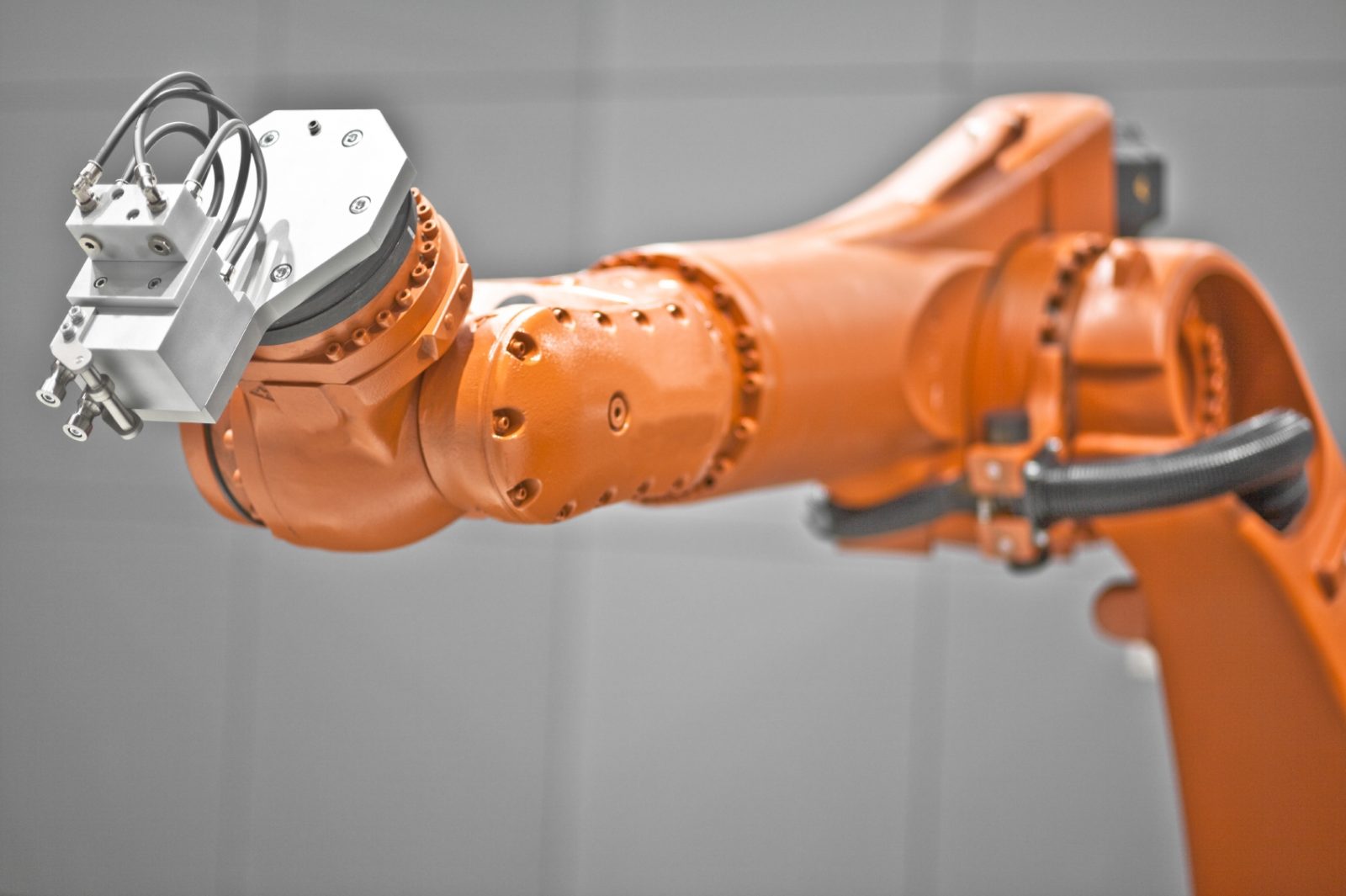

Machine to Machine Communication

Manufacturing floors produce huge amounts of valuable data that can be used for many purposes, but companies must capture it to put the data to work.

Machine to Machine Communication is a term used to describe technology that allows networked devices to exchange information directly to each other, and it is set to disrupt the manufacturing industry. For example, rather than staff maintaining and monitoring machines on the factory floor, sensors can monitor the equipment and the factory’s performance.

Machine to Machine Communication can:

- Reduce unnecessary downtime due to unwarranted maintenance or unexpected repairs

- Increase ability to maintain a precise inventory of spare parts

- Enable machines to share analytics about factory performance and easily identify bottlenecks on the line, respond to conditions to lessen their effect and identify maintenance issues in real time

- Facilitate the transfer of data from a mobile device to another machine to manage how the machine interacts with its environment

- Support remote operation centers, permitting factories to be set up all around the world, managed from a central location, and monitored in real time

- Decrease the number of quality incidents and reduce waste due to more tightly controlled production monitoring

The enablement of IoT through Machine to Machine interaction triggers manufacturing efficiencies and quality performance that previously were unattainable, enables real bottom line changes, and leads to higher net income, driving future innovation or company reinvestment.

Machine to Machine Communication Example: GE’s Durathon Battery Factory

GE’s factory uses 10,000 sensors on the assembly line to report the status of each component in real time which can be viewed via iPad or phone.

Benefits include:

- Real time information on what is actually happening on the factory floor in machines and products

- Rapid decision making when this information is shared within the organization

- Waste reduction; i.e. identifying and removing defective products while on the line

- Continuous data sharing between machines to automatically adjust production speed, eliminating human intervention

- Early failure identification, minimizing line stoppage and emergency repairs

Product Development Process

The IoT drastically changes product development processes. Instead of guessing what a consumer needs, the IoT provides a foundation of information that allows manufacturers to tailor products specifically to a consumer, extending the manufacturing process well beyond the factory floor. Product sensors can relay information back to a manufacturer, informing them of what features are being used, when, where, and how. This insight and real time feedback of how a product is being used blurs the line between product development, manufacturing and product use, and opens up entirely new product applications and markets.

In the previously referenced Interview from the Future on the Birth of Digital Manufacturing, an example is given of a leading digital manufacturer using product data from consumers to recognize that a connected baby monitor was also being used as a bicycle security device. The business then “turned those uses into new app updates available in the cloud, or entirely new products we could simulate.” There are also several real-world examples of the IoT impacting product development.

Product Development Process Examples

- Coca-Cola’s Freestyle vending machine monitors where, when, and how their product is being consumed by connected vending machines

- Bosch created Health Buddy, a device that monitors vital signs and records patient inputs. Instead of being confined to a hospital room, a patient can live in the comfort of his or her home while medical staff remotely monitors their condition

- HP created a printer that automatically orders ink when the printer reaches a certain threshold of pages printed. If used widely, HP could analyze data to determine production schedules of ink demand

- In response to a formerly unknown quality issue, Tesla sent a software update to their vehicles that automatically adjusted the car’s suspension in rough road conditions

In these examples, products are connected devices, providing valuable information to designers that can be used to improve the customer experience or help solve a product development issue. This connectivity allows companies to analyze the data received from the product and tailor it and/or develop the next generation of the product, update it with new features, and adjust to new demands being placed on the product.

The overall result of these product development process changes are an increase in revenue from new products. Shorter design and innovation cycle times, successful target marketing, elimination of extraneous marketing expenses, accurate production forecasting, and lower inventory costs, are all direct benefits of well executed digital innovation efforts.