Revolutionizing Energy Management

A Holistic Approach

Implementing digital technologies for energy management has historically been a cumbersome journey for organizations due to the complexities involved when considering the dependencies of connecting and installing energy meters across production facilities, ensuring the meters are linked to a network infrastructure and setting up the minimum requirements to gather data.

Applying analytics and AI to optimize energy efficiency may seem like a distant goal for many when establishing the foundation of an Energy Management System and connecting meters’ data thoroughly across a plant can take a long time.

By leveraging agile methodologies and data science expertise, your company can develop an approach to streamline energy management and drive faster value and scalability.

Kalypso proposes a Minimum Viable Product (MVP) to scale an agile approach while considering the context of energy, production and quality. By utilizing data science tools at the beginning of your energy management journey, you can drive faster value and scalability.

Energy + Productivity + Quality

The journey starts with not only monitoring energy but also leveraging data for optimization. The first step is contextualizing energy data with production and product information to achieve energy consumption, emissions and productivity efficiency.

The integration of production and quality data diminishes energy loss and optimizes production planning. This helps to reduce energy demand peaks and ready equipment for reducing energy and production costs. In addition, quality data integration enables a series of digital use cases, such as waste management, Statistical Process Control and predictive quality.

The return on investment is realized by not only reducing your energy bill, but also by providing improvements in productivity and quality.

Propelling How Energy Management is Done

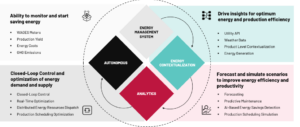

We developed an approach that demystifies and expedites the complexity of the Energy Management journey.

- EMS Deployment: The first stage involves deploying an Energy Management System (EMS), which can be at a single meter level, integrating production and operations data. A new generation of EMS offers advanced capabilities for monitoring and managing energy data, generating automatic data-driven notification of opportunities for improving energy performance and complying with emissions regulations. This can lead to significant energy savings and operational efficiencies. For example, we helped clients achieve annual savings of at least 5% on their energy bills and a 12% reduction in energy losses due to identifying abnormalities and inefficiencies in their equipment.

- Energy Contextualization: Energy consumption needs to be analyzed in the context of production processes. This may be achieved through data integration from other data sources - such as programmable logic controllers (PLC), enterprise resource planning (ERP), Manufacturing Execution System (MES), and weather and utility data. Contextualized data enables powerful use cases like detecting energy consumption anomalies vs. production throughput, detecting energy loss areas with the highest potential for optimization, analyzing energy and production data from a financial standpoint and setting the foundation for the following analytics levels.

- Analytics: Real-time data and analytics optimize how machines and production run, forecast consumption and demand, and simulate production scenarios for the optimum performance of a machine, system, or even a whole plant. Machine learning models and predictive analytics help forecast energy consumption and prescribe actions to optimize processes. These analytics-based methods enable better resource allocation, waste reduction and energy optimization throughout production or even on a single-machine level.

- Autonomous: The next step is to transition from AI helping with analytics to AI running the show autonomously. Transitioning to autonomous control involves AI-driven closed-loop control of equipment parameters, such as through Model Predictive Control (MPC), minimizing operator intervention while maximizing product quality and energy efficiency. Autonomous methods also facilitate distributed energy resource dispatch, which helps supply different sources of energy more efficiently and cost effectively, enabling a lower-carbon future. Production scheduling optimization through AI can also lead to improved efficiency in energy, production and quality.

Sustainability and Environmental Impact

The integration of energy management with production processes not only drives operational efficiency but also contributes to sustainability and environmental targets. By reducing energy consumption, minimizing waste and optimizing resource allocation, businesses can significantly reduce their carbon footprint. Adherence to regulatory standards and emissions reporting also becomes more streamlined with integrated energy management systems.

Case Study

In an EMS Deployment for one solar customer, forecasting and AI-Models were employed to identify energy-savings opportunities. The implemented solution focused on pinpointing panels causing significant losses and addressing challenges such as accurate energy loss calculation through AI pattern detection, root cause analysis via AI-based energy degradation analysis and AI-based potential energy generation calculations. This initiative resulted in:

- 2.5% reduction in power generation

- 100% tamper-proof service log

- 35% increase in solar operations uptime

- Notable 50% reduction in service manpower

The Future of Industry Adoption

As industries strive for greater efficiency and sustainability, the adoption of advanced energy management practices will accelerate.

Technologies such as AI, machine learning and autonomous control will play a pivotal role in shaping the future of energy management.

Organizations that embrace these innovations early on will gain a competitive edge by reducing operational costs, minimizing environmental impact and enhancing overall productivity.

Starting Your Journey

The journey towards revolutionizing energy management requires a paradigm shift in mindset and approach. By integrating digital technologies, data analytics and AI-driven solutions, businesses can unlock new opportunities for efficiency, sustainability, and growth. From deploying advanced energy management systems to harnessing the power of predictive analytics and autonomous control, the possibilities are endless.

Our experience shows that applying such four steps can be simplified by starting on a single meter/equipment level, beginning with the most energy-intensive one on site. By applying these concepts with a narrower scope, the value will be proved faster, and the path to scale to new meters, equipment, lines and sites will be easier and simpler from a technological and business standpoint.

The time to embrace this transformation is now. Together, we can pave the way towards a more sustainable and energy-efficient future for generations to come.