A data-driven approach to yield optimization

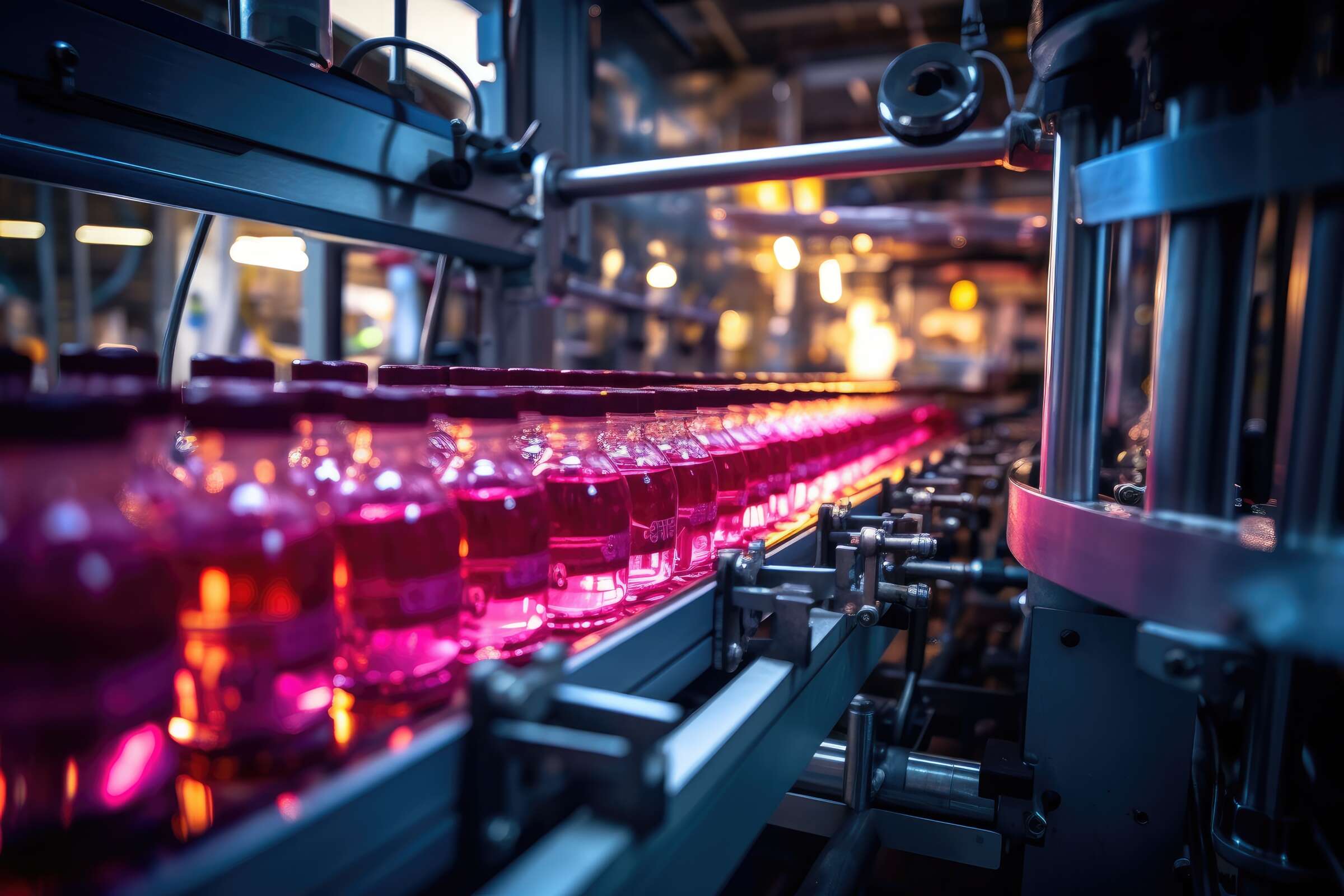

Rising material and energy costs, changing consumer preferences and supply chain disruptions continue to place pressure on manufacturing operations. For CPG leaders, finding process efficiencies while maintaining quality is critical to success.

While Overall Equipment Effectiveness (OEE) has been the gold standard for CPG companies in using data to measure performance, it doesn’t consider performance disparities across different shifts, orders, products and plants. Companies can benefit from a more comprehensive approach.

It's time to move beyond OEE and explore an approach that contextualizes data to generate actionable insights and identify scalable solutions for critical yield challenges.

What's Inside

- How to Maximize Analytics

- Move Beyond OEE to get Deeper Insights

- Identify Targeted Solutions to Fix the Root Cause of Inefficiencies

- Real Results from 5 CPG Case Studies