New Frontiers for Medical Device PLM Systems: Leveraging the Power of Machine Learning

Medical devices are essential to our modern society. They give us healthier, more productive, and more independent lives. But the companies who make them face many headwinds; adhering to strict regulatory standards, proving that their benefits outweigh risks, and achieving efficacy and safety standards. To succeed, they must constantly innovate, drive down costs and navigate complex regulatory pathways.

All of this has been the driving force for medical device manufactures to automate and integrate disparate engineering, quality, regulatory, manufacturing and post-market capabilities into a single consolidated product lifecycle management (PLM) system.

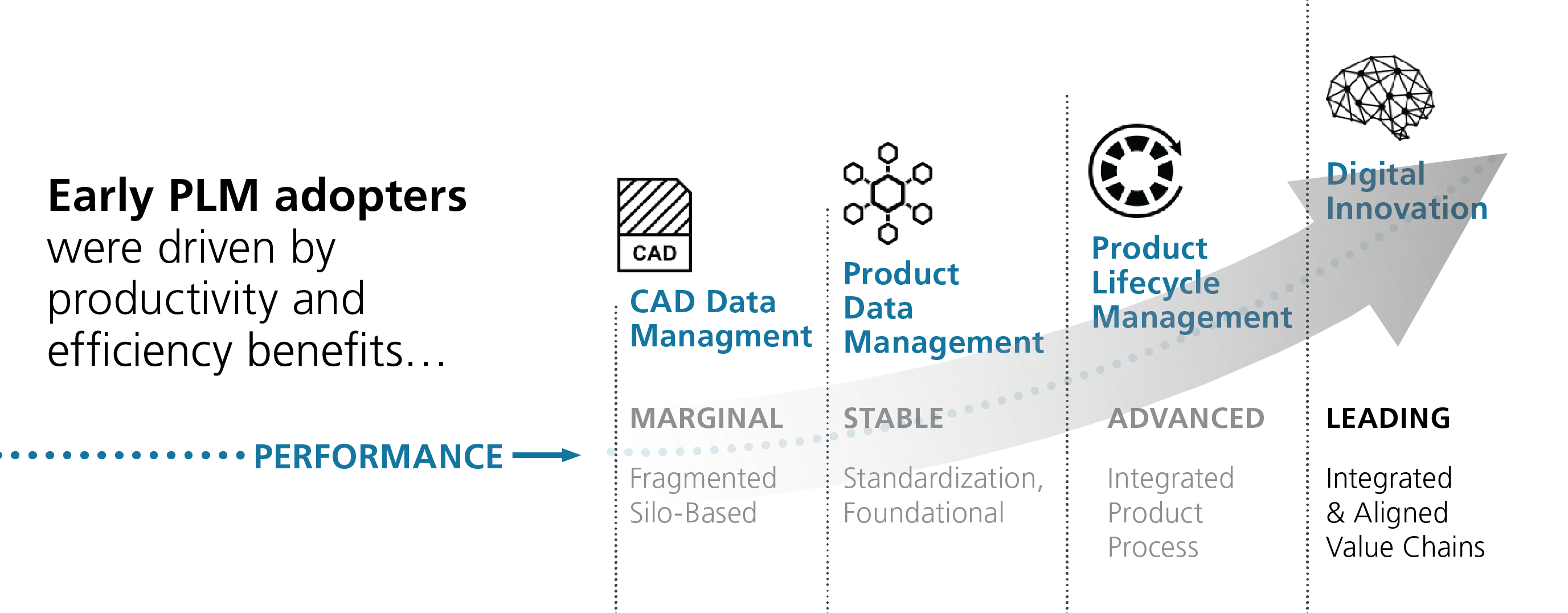

Building on a PLM Foundation

Adopting PLM remains a missed opportunity for much of the medical device industry, with the potential to drive long term transformational success. But we’re rapidly approaching a time when PLM alone is not enough.

The product lifecycle is captured as data – including at its heart, a three-dimensional math-based model of the product. Companies can extend and gain new insight about these product models using new digital technologies, including machine learning, the Internet of Things (IoT), and augmented reality. These technologies have made extraordinary progress in the past few years. By evolving PLM to embrace digital tools, companies gain strategic insights while facilitating the creation of breakthrough products and services.

Machine Learning and PLM

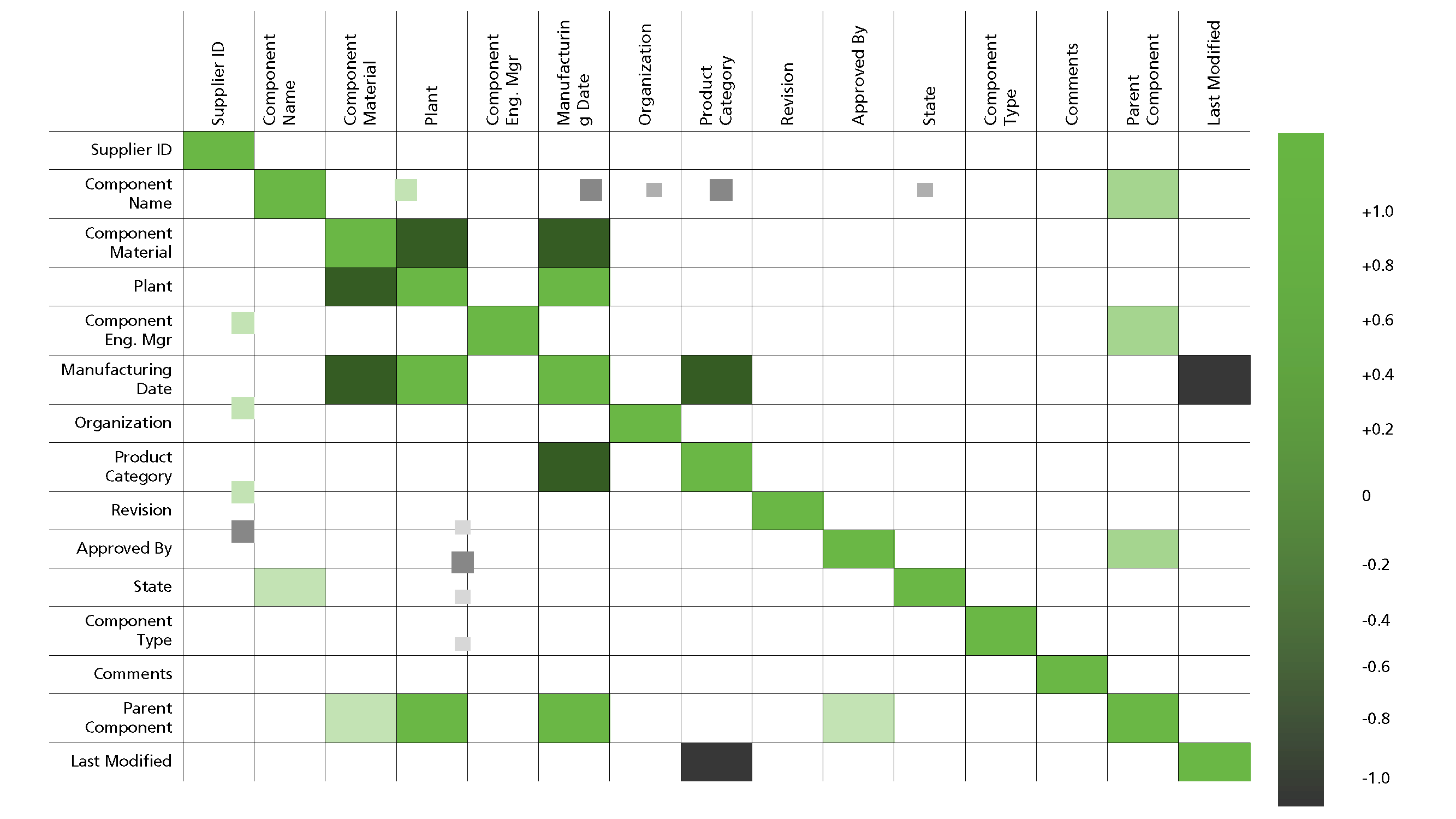

In a typical medical device company, research, engineering, quality engineering, supply chain, operations planning, and post-market surveillance activities produce large sets of structured and unstructured data. Intersections of those data sets can produce over 750 potential points of data correlation. These large, complex, dynamic sets of data are exactly what machine learning analytics algorithms were built for. Any large, mature PLM system with robust processes and data has almost countless applications to drive value from machine learning techniques.

Potential Applications of Machine Learning to PLM

Apply Machine Learning to PLM Data to Improve Product Development Results

PLM provides the potential to gather large amounts of structured product data, and integrate it with data about post-market quality issues. This gives valuable information to improve products, accelerate the resolution of issues and improve quality outcomes.

But even with advanced integrated and automated processes, it’s not easy to identify potential correlations across multiple related data sets. With machine learning performing advanced analytics on PLM data, companies can predict outcomes and improve product development results by understanding the causes behind non-compliances, problem reports, product failures and quality issues.

Understand the Nature of a Product’s Evolution using Natural Language Processing

Any given product may go through thousands, even tens of thousands, of iterations with each change recorded in PLM. By parsing language inside changes (tapping into the same type of technologies that make Siri and Alexa successful), we can understand the historical nature of product improvements and draw insight. This can be helpful in new product development efforts, shaving off design cycles and driving innovation.

What conclusions can we draw from on market sales to identify correlated user experiences? By combining part sales information (say by region) with PLM feature information, we can zero in on market success and tie it to specific product attributes.

Use machine learning to suggest parts based on specification data, and present them to the user. This is similar to how Google Search works when you enter a search term. But this goes beyond search and uses machine learning to identify potential candidates.

The system can learn process and corresponding workflow behaviors over time and by user, site, division, product, etc. From this it can identify points of delay and recommend potential process optimizations. Combined with flexible PLM applications, users can apply optimizations that are sensitive to cultures, locales, product types or even individuals to help processes like change, New Product Development (NPD) and Corrective and Preventive Action (CAPA) run more effectively.

Think Forward. Act Now.

Medical device companies have unique challenges. As they strive to differentiate themselves with new and innovative products, they can get benefit from a strong PLM foundation. With PLM, medical device companies collect large quantities of diverse data as they develop products. But PLM alone can’t provide true insight from this data.

To accelerate results in a digital world, medical device manufacturers need to think forward and act now. Those who identify opportunities to apply machine learning and advanced analytics to PLM will unlock new insights to outpace their competition.