3D Digital Product Creation in Retail: Reinventing the Consumer-Product Interaction

In December 2017, the 3D Retail Coalition (3D.RC) hosted a webcast with famed footwear and apparel brand Vans for a discussion about their revolutionary footwear customization platform, Vans Customs. Below is a summary of the event.

The Featured Speaker

The 3D.RC webinar was centered on the Vans Customs platform, which provides a new online experience for customers to digitally personalize their own versions of Vans’ most famous footwear styles.

Safir Bellali, Vans Global Head of Innovation, shared stories of the journey that brought this innovative new platform to life and reflected on the heritage of the brand that paved the way.

Vans’ Heritage of Customization

Vans, which was born in Anaheim, California in 1966, is now a global brand and the highest grossing in VF Corporation’s broad portfolio. Despite the tremendous growth, Vans has maintained an unwavering commitment to individuality, the “skater lifestyle” and the sleek and timeless performance footwear that made them famous. Today these “Core Classics” styles remain best sellers.

From the beginning, Vans embraced the opportunity to empower their customer, and deepen their connection with the brand, by enabling them to design shoes that represented their personal style.

At the very first store, Vans took individuality to the limits and allowed customers to bring in fabric to create their own personalized shoes. Inspired by this, Bellali and his team set out to bring this spirit of individuality into the digital era with “Vans Customs.”

Footwear Customization Platform

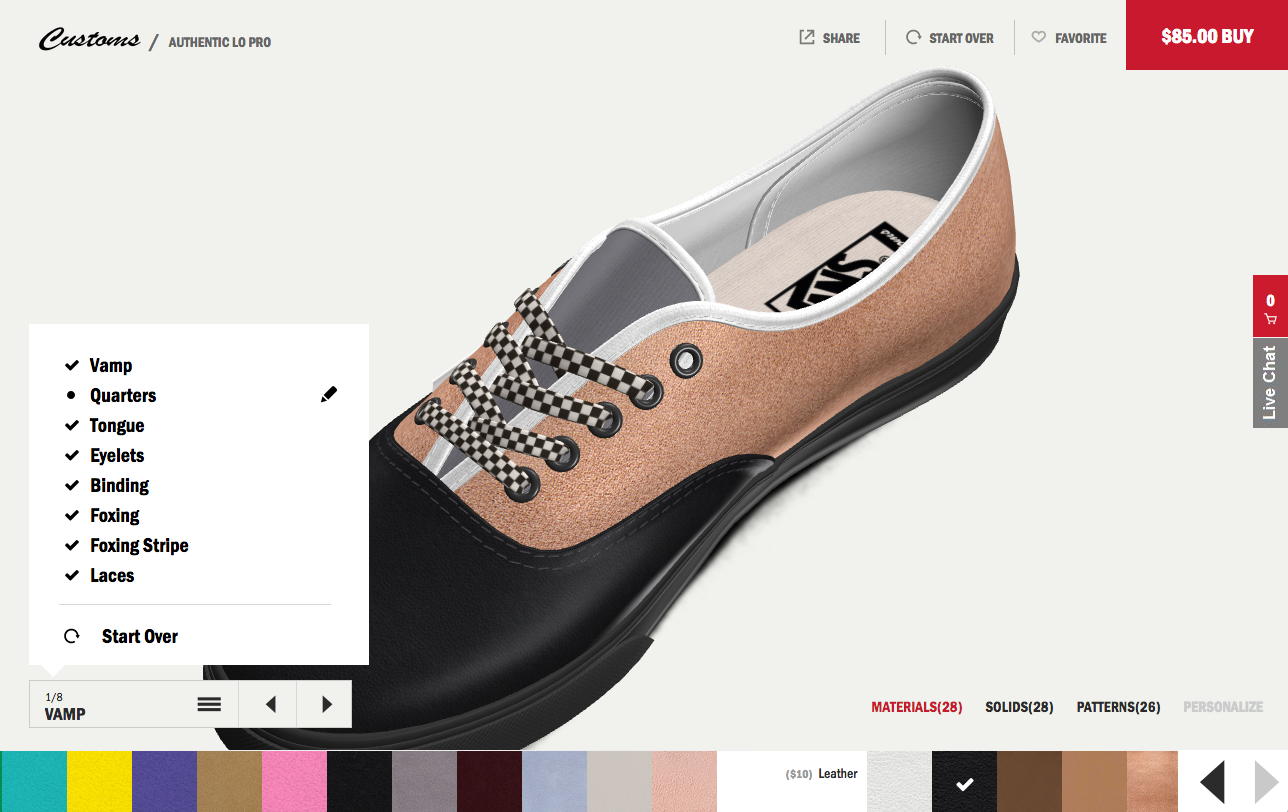

After years in the making, the Vans Customs platform launched in August of this year. The revolutionary online experience allows users to mix and match any fabric from Vans’ extensive library of textiles and apply them to one of Vans’ most famous Core Classics silhouettes to create a shoe that speaks to them.

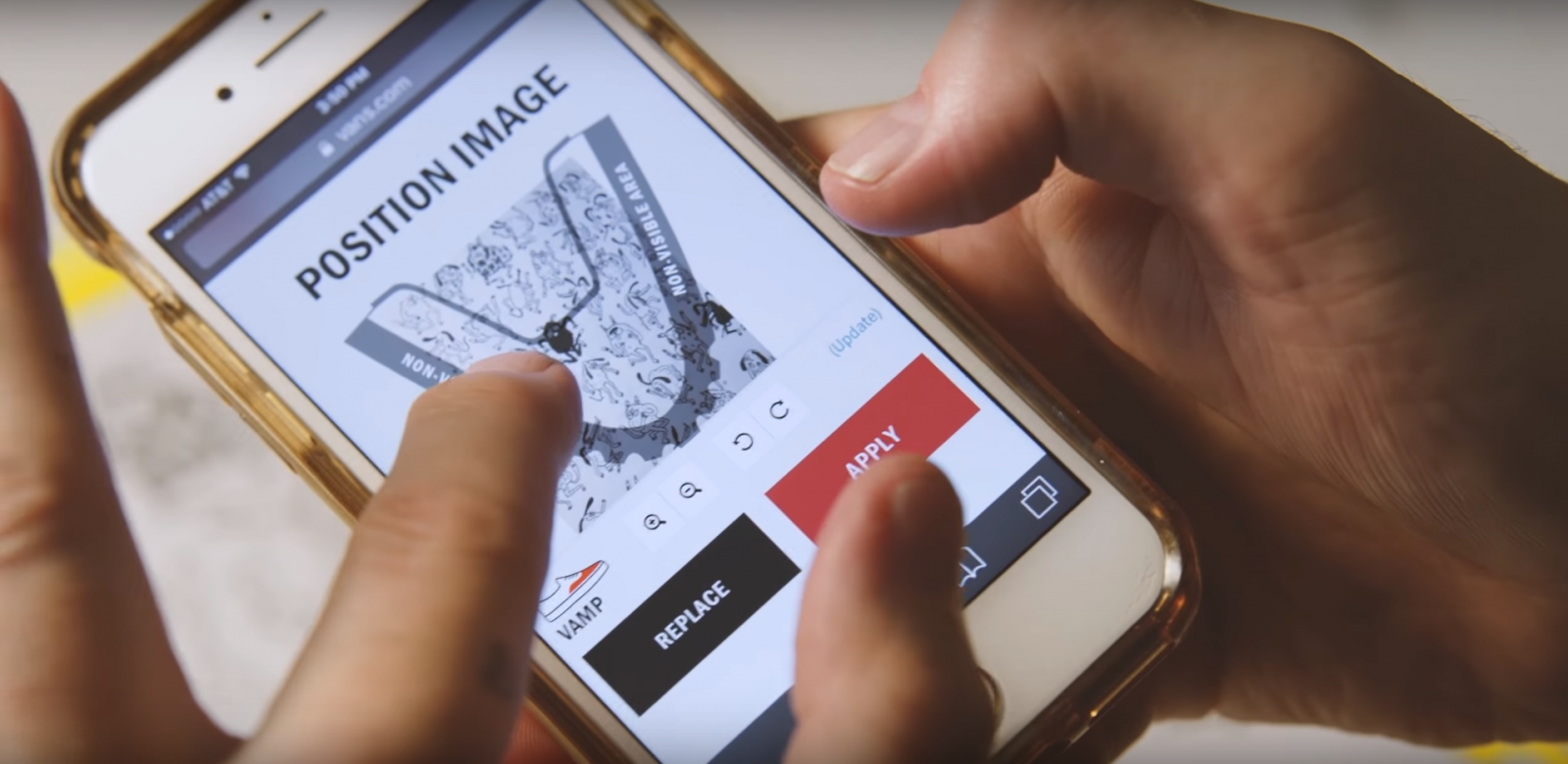

But Bellali and team did not stop there. Inspired by the brand’s original store, the team pushed to create a platform for customers to upload their own image and create fully customized fabric for their shoes within minutes. This digital textile could be scaled, moved, or rotated, and would update on a 3D model in real time. Once satisfied, the customer would purchase the item and the custom kicks were shipped directly within just two weeks!

Developing this platform took the team more than two years and relied heavily on several previous years of work done to digitally reverse engineer their Core Classics styles.

The investment in digitizing these core assets had already proven its value to Vans by allowing designers and developers to rapidly produce digital samples of new materials and colorways on their Classics collection. Replicating these physical samples meant digitally recreating the precise details of each shoe including the stitching, fabric details and imperfections. Doing so required a combination of homegrown tools and off-the-shelf software including Maya, Modo, Keyshot, Rhino, and Cinema4D.

With the 3D models complete, the foundations had been set for the customization platform to be built.

Bellali and team recognized the need to develop a tool that was accessible to customers regardless of the platform they were using, be it a desktop, mobile or tablet device. They also recognized the need to manage proprietary rights and censoring of photos being uploaded by users and establish standards and processes for the returns of customized products. And that was just the beginning.

Physically creating the shoes also required innovative new methods of digital manufacturing. Methods that were of high quality, scalable, cost effective and which adhered to VF’s strict sustainability standards. Not to mention they had to reduce the standard six-week fulfillment time to under two weeks.

Using a battery of advanced manufacturing capabilities including laser cutting, digital printing, dye transfer and robotic automation along with a lean inventory of white canvas shoes, Bellali and team were able to bring Vans Customs off the screen and into real life.

Bringing Custom Shoes to the Masses

With both the consumer and manufacturing platforms in place, Vans now had to get the word out. And buzz began to build after they hosted a number of VIP launch parties at the new Vans headquarters in Costa Mesa, CA.

At each event, guests were encouraged to send in photos or patterns that they wanted featured on their own custom kicks. Then the team highlighted the innovative new manufacturing processes by producing the shoes on-site for the media and VIPs to see.

Before long, social media was abuzz about the new platform. A momentum that was sustained by providing Instagram and Facebook integrations that encouraged users to upload and share pictures of their new shoes with friends and followers.

The brand also leveraged its deep roots in the skating community to have popular skaters and snowboard athletes create their own custom footwear designs for customers to find and buy themselves.

What’s on The Horizon?

For Bellali, innovation at Vans has always been about “leveraging technology to help deliver amazing and authentic experiences for customers.” And although thrilled with the initial success of the new platform, the team is committed to evolving Vans Customs alongside the latest technologies, to push the boundaries of the customer experience and to embrace the future as leaders in the digital retail revolution.

For more, download the slides from the webinar, and learn about how to join the 3D revolution online at 3drc.pi.tv.

About the 3D.RC

The 3D Retail Coalition (3D.RC) is a collaborative group of global retailers and brands, working together to advance 3D technology for apparel, accessories, and footwear retailers/manufacturers. Our mission is to provide resources and networking opportunities to help members unlock and accelerate the potential value of 3D visualization and virtualization, while maximizing positive impact within their organizations.

The group is open to any retailer/brand currently using (or planning to use) 3D technology.